3D metal printing offers opportunities for many different sectors - University of Vaasa's Metal Additive Manufacturing Lab is used by various organisations, researchers and students

3D printing has revolutionised the industry, bringing unique opportunities for design and the manufacture of customized parts in a variety of sectors. Metal printing is a relatively new, but rapidly growing 3D printing technology. It can be used to produce complex, highly accurate, lightweight and unique components that would be difficult or impossible to produce using traditional manufacturing methods.

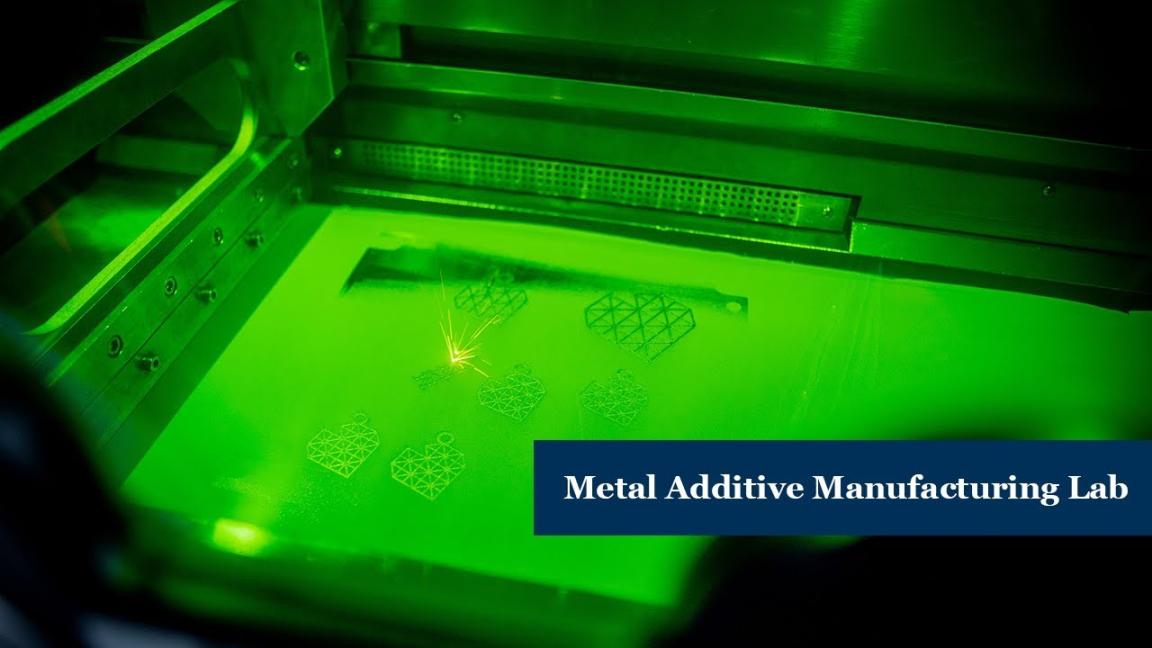

Metal printing, like other printing methods, is done layer by layer. Metal powder is melted by focus laser in an inert gas chamber. Components are designed using tools such as virtual glasses and 3D scanners, as well as more traditional 3D printers, of which the University of Vaasa has around 20.

The materials used for 3D metal printing are mostly stainless steel, titanium or aluminium and nickel-chromium-based superalloy inconel, which can tolerate very high temperatures. The printing of components takes several hours, depending on the size of the part. 3D metal printing is most widely used in the aerospace, medical and automotive industries.

The University of Vaasa's 3D metal printing laboratory offers companies and organisations services ranging from consultancy to design and component manufacturing from start to finish. The laboratory also offers many opportunities for researchers and students.

For more information

University Lecturer Rayko Toshev, 029 4498370, rayko.toshev@uwasa.fi

Laboratory Engineer Miguel Zamora Cordero, 029 4498752, miguel.zamora@uwasa.fi