Next Generation TB (NGTB)

Project information

Project description

In Vaasa, there is the most significant hub for electrical and energy technology expertise in the Nordic countries, characterized by the mutual integration of industry companies and higher education institutions. There is also specific expertise in digitalization and robotics related to manufacturing industries. Technobothnia is a joint educational and research laboratory complex of the University of Vaasa, Vaasa University of Applied Sciences, and Yrkeshögskolan Novia. The current equipment at Technobothnia is partially outdated and no longer meets the needs of Research, Development, and Innovation (RDI) activities, industry collaboration, and educational activities required by the dual transition. The investments in the group project enable the updating of Technobothnia's RDI environments to meet future needs. The project planning has been done in collaboration between Vaasa University of Applied Sciences, Yrkeshögskolan Novia, and the University of Vaasa, based on the common vision of Technobothnia's owners regarding the development needs arising from the Industry 5.0 transition.

In a clean transition, energy production and consumption shift to electricity-based, either directly or indirectly. The NGTB project strengthens the dual transition by combining digitalization with specific expertise in electrical and energy technology and measurement technology to meet the needs of the industry. The investments have significant implications for the energy industry, the development of offshore wind turbines, autonomous maritime transport, surveying technology, and the construction sector. The project's realization enhances the expertise of the Vaasa energy hub and increases the attractiveness of the region. The implementation of the project is important from the perspective of investments directed towards Ostrobothnia. The acquisitions made in the project enable a more versatile use of Technobothnia for teaching and research throughout Finland.

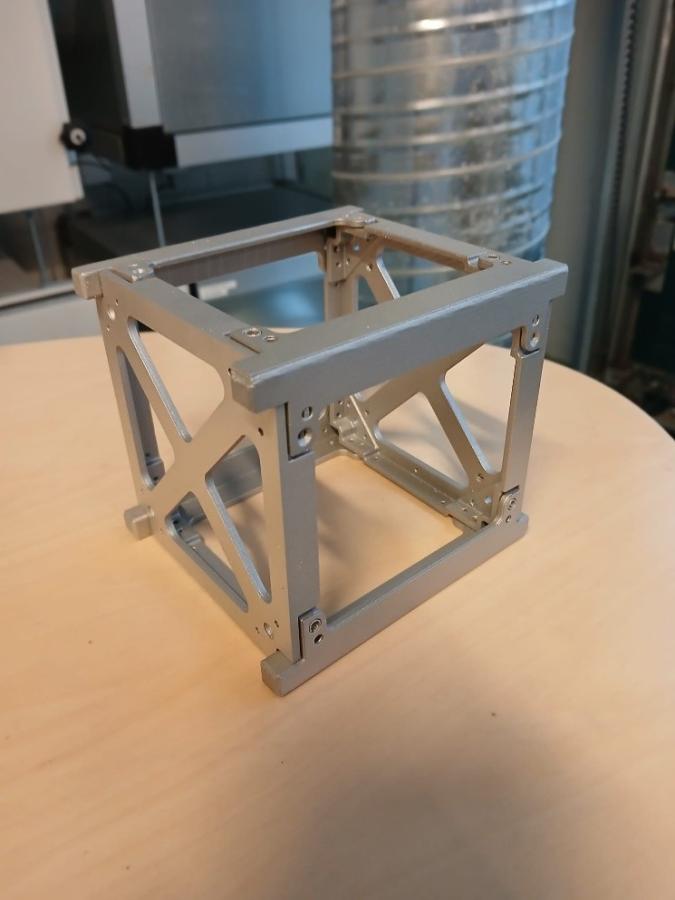

The key goal of the sub-project of the University of Vaasa is to upgrade the technology of the Metal Additive Manufacturing laboratory to a new level by diversifying the material selection and expanding the possibilities for the use of reactive and non-reactive metals. The project involves software acquisitions related to topology optimization and expands the material repertoire of metal printing through equipment acquisitions, including reactive materials such as aluminum and cobalt-chrome. Both measures together promote the technical development of the laboratory and its ability to respond to the needs of local companies. As a result of these measures, the laboratory will rise to a new level in terms of technology and expertise, creating positive impacts on local industry and innovation activities. The development of laboratories and the update of the service offering are carried out in collaboration with VAMK in the project.